Desoltik

Automated Semiconductor Reconditioning

Goal: Enabling a sustainable circular economy in the electronics industry by developing an automated semiconductor reconditioning system. The aim is to reduce the costs of reuse and utilize the maximum service life while saving resources at the same time.

I co-founded the start-up Desoltik together with three other companies, the idea for which originated in the Student Innovation Lab at KIT. Inspired by the chip crisis in 2022, we realized how dependent we are on the semiconductor industry and how fragile the supply chains are. At the same time, electronic waste is growing immensely, although it still contains many important resources, not only the materials, but also the semiconductors themselves, some of which have a much longer lifespan. In order to take advantage of these challenges and opportunities, we came up with the idea of how to access these semiconductors efficiently and minimally invasively without damaging them, but still recovering them in a highly flexible way and in large quantities.

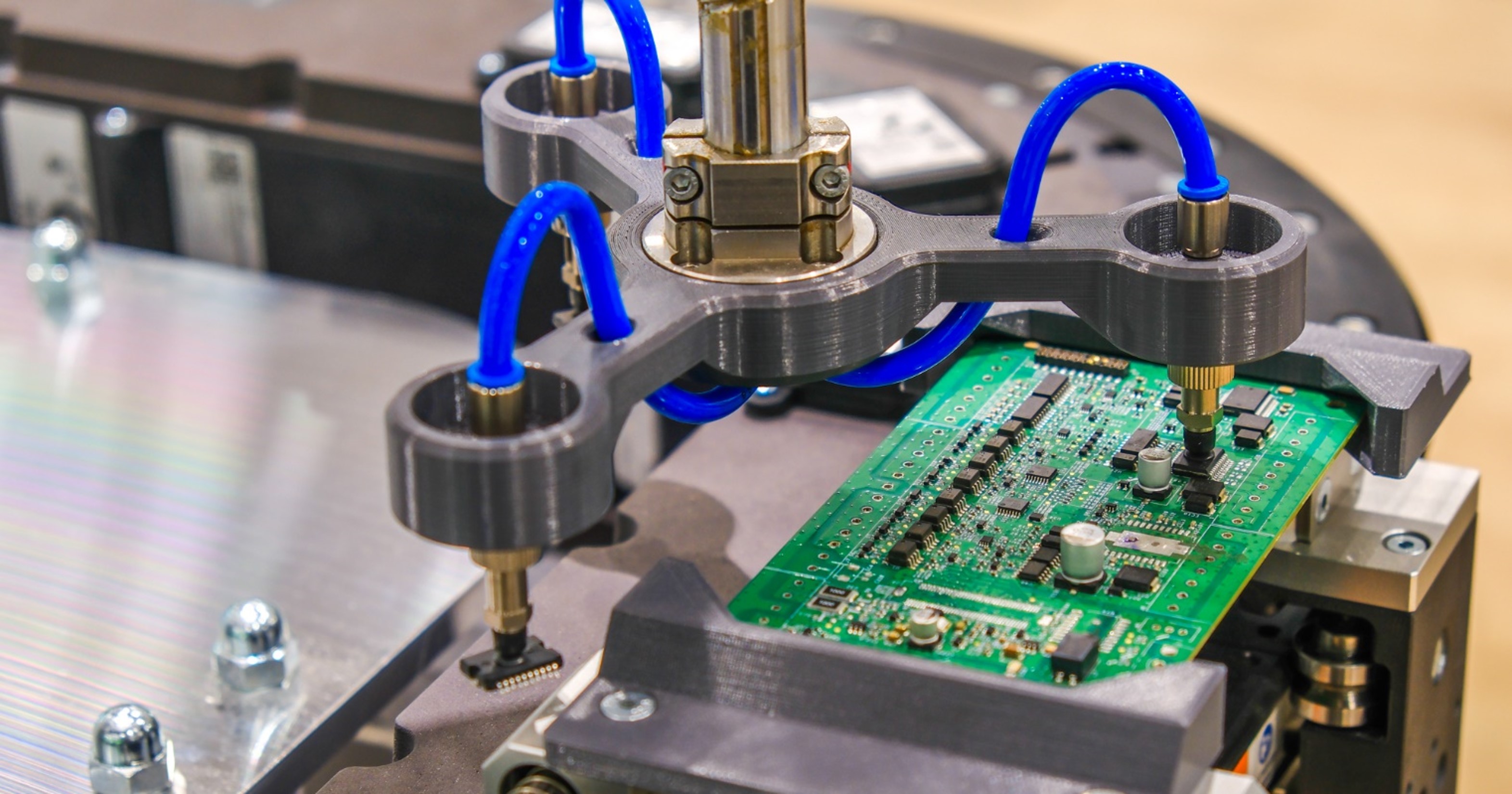

Supported by the wbk nstitute of Production Science, we were able to develop our first prototype, with which we were able to successfully desolder the first semiconductors. The focus here was on technical feasibility and generating knowledge.

With this prototype we won the Best Product Award 2023 at the Student Innovation Lab

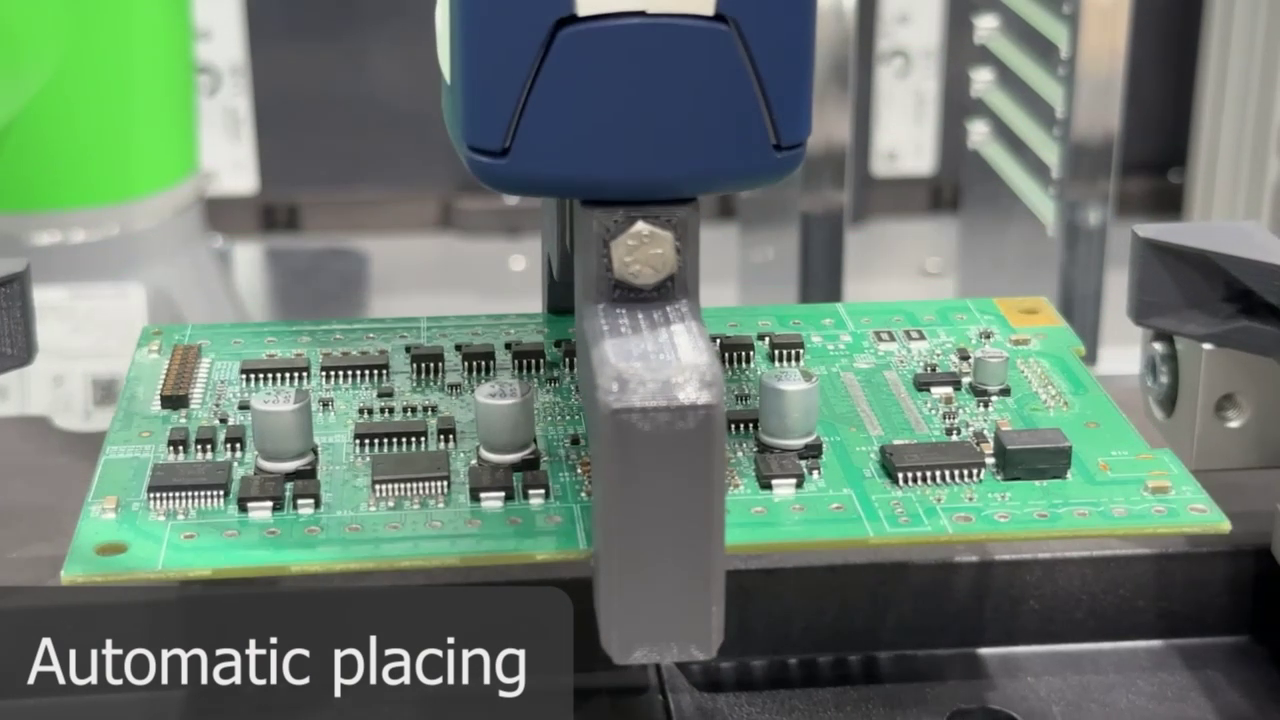

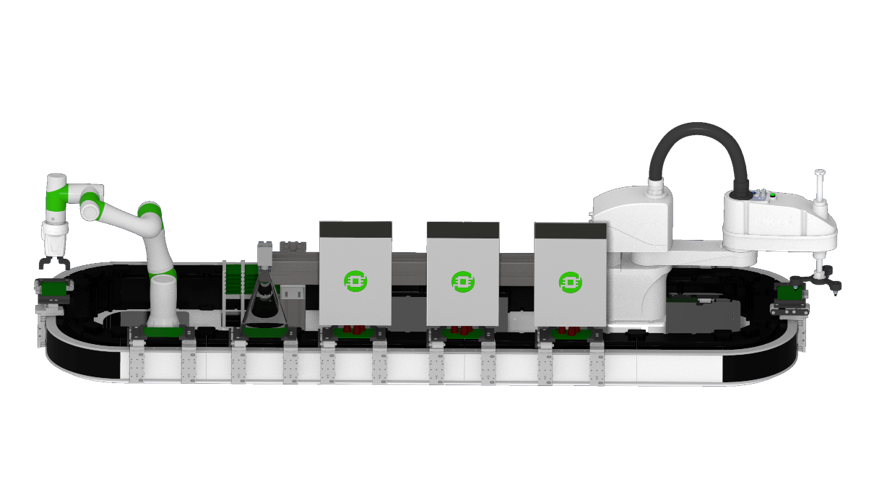

As a result, Schneider Electric became aware of us and together we developed another prototype, which we exhibited as a show case at the Smart Production Solutions (SPS) in Nuremberg and later together with SAP at the central showcase at SAP Sapphire in Orlando and Barcelona. The focus of this project was on automating the process.

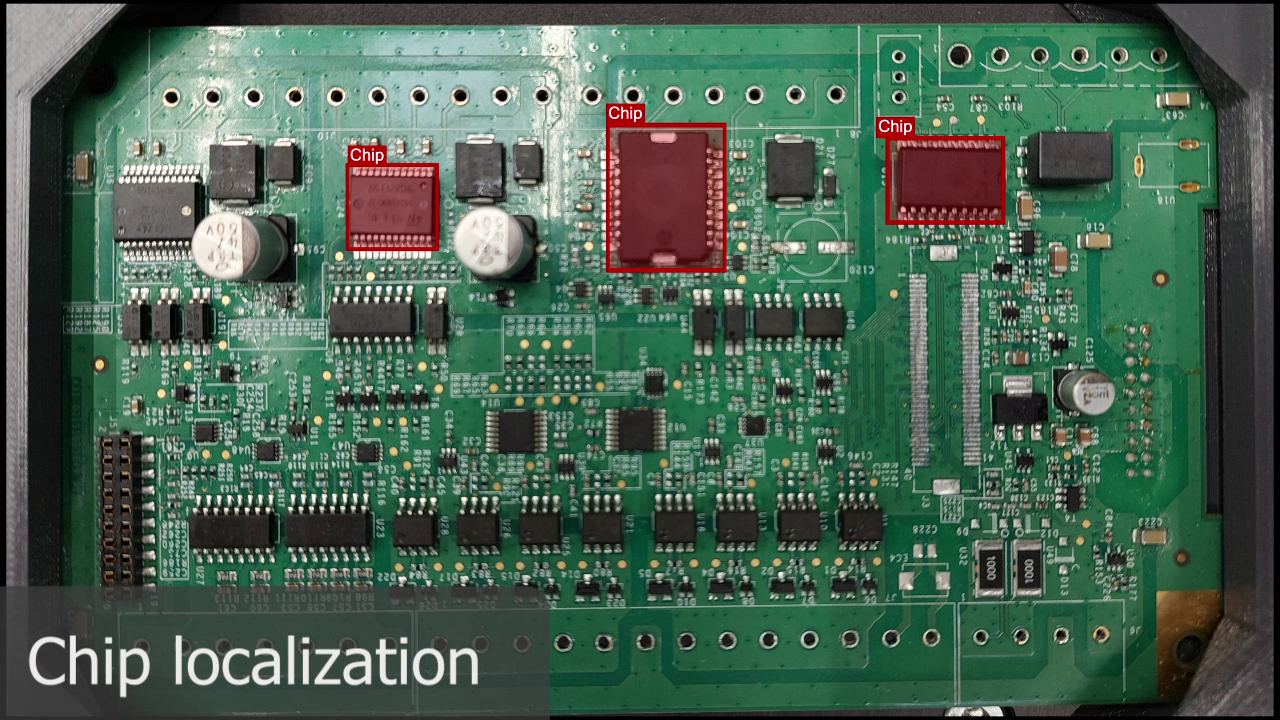

Technically, the idea is to parallelize the process, where the difficulty lies in estimating the temperature on the surface (not a single point), because you need a very precise temperature measurement to damage the semiconductors as little as possible. We have combined machine learning methods with system modeling to make this possible. In addition, we have developed a parallelized process to process several samples in parallel and to time the removal optimally. Another challenge is the high degree of flexibility, which requires very flexible fixtures and localization algorithms.